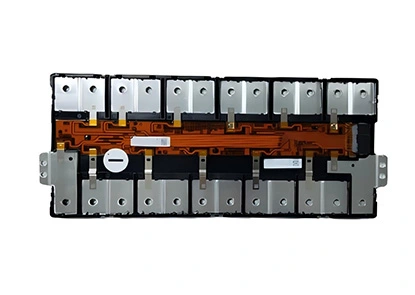

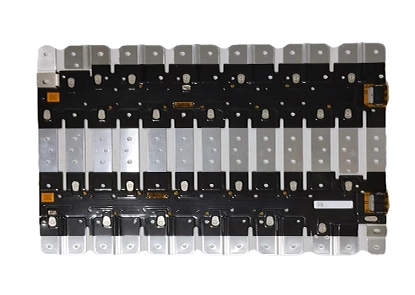

CCS(Cell Contact System / 电芯连接系统)将信号采集组件、塑料结构件和铝排组合在一起,它们通过热铆工艺或热压工艺连接,应用于新能源汽车和储能电池模块,实现电芯串并联、温度和电压采样,并将信息传输到BMS系统。CCS 作为电池模块或电池包内部电气连接元件,其取样元件、生产工艺、材料选择等受电芯分组方式、电池组校准参数、使用环境、空间、重量等因素的影响。因此,为了满足应用端的多样化需求,CCS产品也在不断升级信号采集组件、优化集成工艺等,并开发了多种技术路线。

CCS 电池模组以其卓越的安全性和可靠性而闻名。

严格的质量控制

每个电池模组都经过严格的质量测试,以确保在各种应用中的稳定性能。

先进的制造工艺

利用最先进的制造技术,我们确保电池模组的高效率和长使用寿命。

多重安全保护

配备过充、过放、短路保护等多重安全机制,确保使用过程中的安全。

延长使用寿命

通过优化的设计和材料选择,我们的电池模组使用寿命长,降低了更换频率。

CCS 电池模块具有很高的安全性和可靠性,是广泛应用的理想之选。无论您需要电动汽车 / EV电池还是储能系统 / BESS 电池,CCS 电池模块都能提供最可靠的解决方案。

请致电我们:

请致电我们:  Email Us:

Email Us:  福建省厦门市海沧区后祥路198号

福建省厦门市海沧区后祥路198号